Customized Toys Molding Bases With Honing True Round Guide Sleeve Increasing 20% Molds Free Drawing Review & Fine Quotat

Product Description:

Custom Mold Bases is a professional mold base manufacturer that specializes in customized mold bases with various sizes and materials. Our mold bases are designed to meet the requirements of customers for their daily necessities, toys, cosmetics, electrical appliances, medical equipment, etc. Our mold bases are available in sizes ranging from 15*15cm to 60*70cm. With our extensive material selection, including 50c, ASTM: 1050, JIS: S50c, DIN: CK53, ASTM: P20, ASTM: P20+Ni(DIN: 1.2738), ASTM: 420(DIN: 1.2083), ASSAB: S136, ASTM: P21(Japan: ), ASTM: H13(DIN: 1.2344, JIS: SKD61, ASSAB: 8407), customers are able to find the most suitable material for their applications.

Our Custom Mold Bases comes with a tax-inclusive price that includes 13% value-added tax. The quoted price does not include the freight, and the freight will be calculated separately before the order is confirmed. For safety considerations, we use fumigation-free wooden box for packaging.

Our Custom Mold Bases are designed to meet customers’ requirements with superior quality and excellent service. Customers can trust that our Custom Mold Bases will meet their needs and expectations.

Features:

- Product Name: Custom Mold Bases

- Service: Free Drawing Review. Accurately Inform You Of The Delivery Time. Fine Quotation, Listing All Processing Items And Detailed Costs. 24-hour On-duty Professional After-sales Service Team. Solve Problems At The First Time And Then Implement Responsibilities Without Wasting Time On Determining Responsibilities. After-sales Survey To Understand Usage.

- Packaging: Fumigation-free Wooden Box

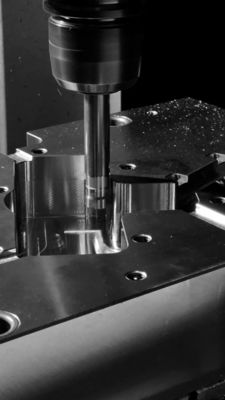

- Surface Treatment: Precision Milling, Precision Grinding

- Product selection:

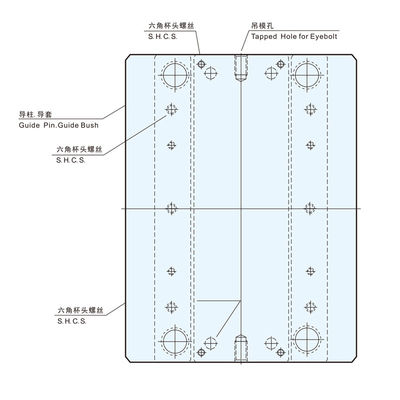

- In Addition To Standard Mould Base, Can Other Processing Projects Be Done For Mold Frame Products?

- The Following Additional Processing Projects Can Be Done For Mould Base Products: AB Plate And Push Plate Change Steel Type, Rough (fine) Frame Processing, Precision Frame Chamfering, Round Frame, Back Needle Through Push Plate, Limit Pin, Guide Post Inversion, Standard Needle. Plate Edge (EGP), Standard Code Mould Pit, Fine Work Surface Code Mould Pit, Top Stick Hole, Side Lock (SIDELOCK), Top Lock (TOPLOCK), Oblique Guide Position Assistant (TAPERBLOCK), Suction Nozzle. Hole, Code Die Iron (locking Module).

- If The Above Processing Projects Cannot Meet Your Needs, Please Contact Us Directly.

- Material: 50c, ASTM: 1050, JIS: S50c, DIN: CK53, ASTM: P20, ASTM: P20+Ni(DIN: 1.2738), ASTM: 420(DIN: 1.2083), ASSAB: S136, ASTM: P21(Japan: ), ASTM: H13(DIN: 1.2344, JIS: SKD61, ASSAB: 8407)

Technical Parameters:

| Parameters |

Specifications |

| Processing |

CNC Machining (Mazak/ Okuma/ Mori Seiki/ Makino, Etc) |

| Product selection |

In addition to standard mould base, can other processing projects be done for mold frame products? The following additional processing projects can be done for mould base products: AB Plate and Push Plate Change Steel Type, Rough (fine) Frame Processing, Precision Frame Chamfering, Round Frame, Back Needle Through Push Plate, Limit Pin, Guide Post Inversion, Standard Needle. Plate Edge (EGP), Standard Code Mould Pit, Fine Work Surface Code Mould Pit, Top Stick Hole, Side Lock (SIDELOCK), Top Lock (TOPLOCK), Oblique Guide Position Assistant (TAPERBLOCK), Suction Nozzle. Hole, Code Die Iron (locking Module). If the above processing projects cannot meet your needs, please contact us directly. |

| Surface Treatment |

Precision Milling, Precision Grinding |

| Delivery |

Non-standard customized mould base: Range 15*15cm-80*130cm; Normal Production Time 5-12 Days |

| Color |

Steel |

| Size |

15*15cm*80*130cm

|

| Standards |

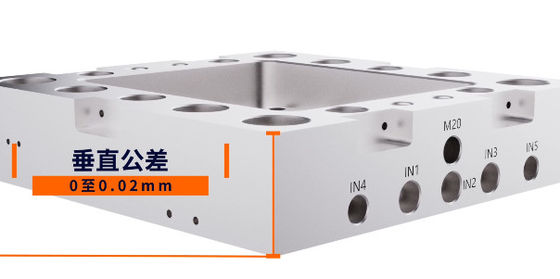

1. Honing true round guide sleeve can effectively increase the number of opening and closing moulds by 20%, prevent guide post from being pulled and improve the service life of the mould. 2. Customized 50c material, hardness HB=160-180. Higher hardness, lower deformation rate, better finish and better rust resistance than ordinary steel(hardness 140-170). 3. The whole set of screw teeth use CNC extrusion teeth process, smooth screw teeth, easy to disassemble and assemble. 4. The screw head is processed by CNC sinking, the bottom of the hole is flat, and the locking performance is better. 5. The square iron screw hole is processed by CNC, with good verticality. 6. The plate thickness tolerance is +0-0.1mm. Prepare pre-customizable accessories to shorten the mould production time. 7. Imported equipment: MAZAK, OKUMA, MORI SEIKI, MAKINO, with accurate repeated positioning and precision hole and frame tolerance of 0.01mm and good finish. 8. Using high-end imported cutting tools (Swiss Sandvik and Japanese BIG) to improve the straightness and precision of holes and frames and the accuracy and finish of the entire processing of the mould base. |

| Packaging |

Fumigation-free wooden box |

| Logo |

Customized |

| Application |

Daily Necessities, Toys, Cosmetics, Electrical Appliances, Medical Equipment, Etc. |

Applications:

Customized mold bases are an essential part of the industrial production process, and DXM offers a wide range of custom mold bases to meet the production needs of different customers. Certified by ISO9001:2015, DXM's custom mold bases are of superior quality and reliable performance. The minimum order quantity is 1 and the price will be quoted according to the drawings and processing requirements you provide. They are all packaged in fumigation-free wooden boxes and sent out by sea transportation in containers. The delivery time is generally 5-12 days for non-standard customized mould base. The range of product size is from 15*15cm to 80*130cm. We offer a variety of payment options, and all orders can be invoiced with VAT special invoices. The annual supply capacity is 200 sets. The materials used are steel, and the color is steel. In addition to standard mould base, other processing projects for mold frame products can be done, such as AB plate and push plate change steel type, rough (fine) frame processing, precision frame chamfering, round frame, back needle through push plate, limit pin, guide post inversion, standard needle. Plate edge (EGP), standard code mould pit, fine work surface code mould pit, top stick hole, side lock (SIDELOCK), top lock (TOPLOCK), oblique guide position assistant (TAPERBLOCK), suction nozzle. Hole, code die iron (locking module). The quotation provided by DXM includes 13% value-added tax, but does not include freight, which will be calculated separately before the order is confirmed.

Customization:

Custom Mold Bases from DXM are the perfect solution for your custom mold requirements. Our custom mold bases are designed to meet your exact specifications, with a range of 15*15cm-80*130cm and a production time of 5-12 days. All our products are certified ISO9001:2015 and come with a minimum order quantity of 1. The materials available include 50c, ASTM: 1050, JIS: S50c, DIN: CK53, ASTM: P20, ASTM: P20+Ni(DIN: 1.2738), ASTM: 420(DIN: 1.2083), ASSAB: S136, ASTM: P21(Japan: ), ASTM: H13(DIN: 1.2344, JIS: SKD61, ASSAB: 8407). We provide a very diverse range of payment methods, and all orders can be invoiced with a VAT special invoice. Our supply ability is 290000 sets/year, and we offer free drawing review, accurately informing you of the delivery time, fine quotation, listing all processing items and detailed costs, 24-hour on-duty professional after-sales service team, solve problems at the first time and then implement responsibilities without wasting time on determining responsibilities, and after-sales survey to understand usage. All exported products are packaged in fumigation-free wooden boxes and transported to designated ports by sea transportation using containers.

Support and Services:

Custom Mold Bases Technical Support and Service

At Custom Mold Bases, we provide top-tier technical support and service for all our customers. Our technical support team is available 24/7 to answer any questions you may have about our products and services.

We provide comprehensive installation and maintenance services to ensure our products are functioning optimally. We also offer a variety of custom solutions for our customers, giving them the best possible experience.

Our customer service team is available to provide assistance with any issue you may have. We strive to provide the highest level of customer satisfaction and will do our best to ensure your success.

Packing and Shipping:

Custom Mold Bases packaging and shipping include:

- Securely packing the product to ensure safe arrival

- Using appropriate shipping method to meet customer's needs

- Including all necessary documents with the shipment

- Providing tracking information as soon as the shipment leaves our facility

FAQ:

- Q: What is the Brand Name of Custom Mold Bases?

- A: The Brand Name of Custom Mold Bases is DXM.

- Q: What is the Model Number of Custom Mold Bases?

- A: The Model Number of Custom Mold Bases is Customized Large water mouth system mould base.

- Q: Where is the Place of Origin of Custom Mold Bases?

- A: The Place of Origin of Custom Mold Bases is Guangdong, China.

- Q: What is the Certification of Custom Mold Bases?

- A: The Certification of Custom Mold Bases is ISO9001:2015.

- Q: What is the Minimum Order Quantity of Custom Mold Bases?

- A: The Minimum Order Quantity of Custom Mold Bases is 1.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!