15*15cm*80*130cm Plastic Mould Base DIN CK53 Material Free Drawing Review Accurate Delivery Time Information

Plastic Mould Base is a customized product with a variety of options and features. It is made of steel and manufactured through CNC machining (Mazak / Okuma / Mori Seiki / Makino, etc.), precision milling, and precision grinding. In addition to standard mould base, it also offers other processing projects for mould frame products. These include: AB Plate and Push Plate change steel type, rough (fine) frame processing, precision frame chamfering, round frame, back needle through push plate, limit pin, guide post inversion, standard needle. Plate edge (EGP), standard code mould pit, fine work surface code mould pit, top stick hole, side lock (SIDELOCK), top lock (TOPLOCK), oblique guide position assistant (TAPERBLOCK), suction nozzle. hole, code die iron (locking module). If the above processing projects cannot meet your needs, please contact us directly.

Features:

- Product Name: Plastic Mould Base

- Logo: Customized

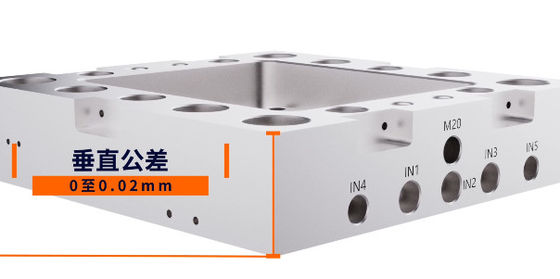

- Surface Treatment: Precision Milling, Precision Grinding

- Shape: Customized

- Delivery: Non-standard Customized Mould Base: Range 15*15cm-80*130cm; Normal Production Time 5-12 Days

- Processing: CNC Machining(Mazak / Okuma / Mori Seiki / Makino, Etc)

Technical Parameters:

| Parameters |

Description |

| Material |

50c, ASTM: 1050, JIS: S50c, DIN: CK53 |

| Shape |

Customized |

| Size |

15*15cm*80*130cm

|

| Service |

Free Drawing Review. Accurately Inform You Of The Delivery Time. Fine Quotation, Listing All Processing Items And Detailed Costs. 24-hour On-duty Professional After-sales Service Team. Solve Problems At The First Time And Then Implement Responsibilities Without Wasting Time On Determining Responsibilities. After-sales Survey To Understand Usage. |

| Logo |

Customized |

| Delivery |

Non-standard Customized Mould Base: Range 15*15cm-80*130cm; Normal Production Time 5-12 Days |

| Packaging |

Fumigation-free Wooden Box |

| Quotation |

1. Is The Quotation From DXM A Tax-inclusive Price? ● Yes, DXM's Quotation Includes 13% Value-added Tax. 2. Does DXM's Quotation Include Freight? ● The Product Quotation Does Not Include Freight, And The Freight Will Be Calculated Separately Before The Order Is Confirmed. |

| Processing |

CNC Machining(Mazak / Okuma / Mori Seiki / Makino, Etc) |

| Surface Treatment |

Precision Milling, Precision Grinding |

Applications:

Plastic Mould Base, branded as DXM, is a simplified type fine water mouth system mould base certified by ISO9001:2015. It is made of 50C, ASTM 1050, JIS S50C, and DIN CK53 material and can be customized in shape. Its minimum order quantity is 1, and the price is quoted according to the drawings and processing requirements you provided. It can be processed by precision milling and grinding, and surface treatment. It is packaged in fumigation-free wooden boxes and transported to designated ports by sea transportation using containers, with a delivery time of 5-12 days for non-standard customized mould base in sizes ranging from 15*15cm to 80*130cm. We provide a very diverse range of payment methods and all orders can be invoiced with VAT special invoices. Our supply ability is 200 sets/year. We can do additional processing projects such as AB Plate And Push Plate Change Steel Type, Rough (fine) Frame Processing, Precision Frame Chamfering, Round Frame, Back Needle Through Push Plate, Limit Pin, Guide Post Inversion, Standard Needle. Plate Edge (EGP), Standard Code Mould Pit, Fine Work Surface Code Mould Pit, Top Stick Hole, Side Lock (SIDELOCK), Top Lock (TOPLOCK), Oblique Guide Position Assistant (TAPERBLOCK), Suction Nozzle. Hole, Code Die Iron (locking Module). If the above processing projects cannot meet your needs, please contact us directly.

Customization:

Are you looking for a custom Plastic Mould Base? DXM offers a wide range of Plastic Mould Base with certification of ISO9001:2015. The model number is Custom Simplified type fine water mouth system mould base. The minimum order quantity is 1. The price, packaging details, delivery time, payment terms, supply ability, surface treatment, product selection, color, processing, and size are all customizable. The size range is from 15*15cm*80*130cm. The surface treatment can be precision milling, or precision grinding. The product selection includes AB Plate and Push Plate Change Steel Type, Rough (fine) Frame Processing, Precision Frame Chamfering, Round Frame, Back Needle Through Push Plate, Limit Pin, Guide Post Inversion, Standard Needle. Plate Edge (EGP), Standard Code Mould Pit, Fine Work Surface Code Mould Pit, Top Stick Hole, Side Lock (SIDELOCK), Top Lock (TOPLOCK), Oblique Guide Position Assistant (TAPERBLOCK), Suction Nozzle. Hole, Code Die Iron (locking Module). If the above processing projects cannot meet your needs, please contact us directly. All orders can be invoiced with VAT special invoices.

Support and Services:

Technical Support & Service for Plastic Mould Base

We provide technical support and service for our Plastic Mould Base. Our experts are available to help you with any questions you may have about the product.

We offer a range of services, including but not limited to:

- Design and engineering advice

- Troubleshooting and repair

- Installation and commissioning

- Upgrades and maintenance

- Training and documentation

If you have any questions or need help, please don't hesitate to contact us. We look forward to hearing from you.

Packing and Shipping:

Packaging and Shipping of Plastic Mould Base:

The Plastic Mould Base will be packaged in a corrugated cardboard box with internal foam cushioning. It will be securely sealed to ensure safe shipping and delivery. The box will be labeled with the product name and a barcode or serial number. Special care will be taken to ensure that the Plastic Mould Base is handled properly during shipping.

FAQ:

FAQs:

Q1: What is the Brand Name and Model Number of the Plastic Mould Base?

A1: The Brand Name is DXM and the Model Number is Custom Simplified type fine water mouth system mould base.

Q2: Where is the Place of Origin?

A2: The Place of Origin is Guangdong, China.

Q3: What is the Certification?

A3: The Certification is ISO9001:2015.

Q4: What is the Minimum Order Quantity?

A4: The Minimum Order Quantity is 1.

Q5: How much is the Price and what is the Packaging Details?

A5: The Price is Quotation according to the drawings and processing requirements you provided. All exported products are packaged in fumigation-free wooden boxes and transported to designated ports by sea transportation using containers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!